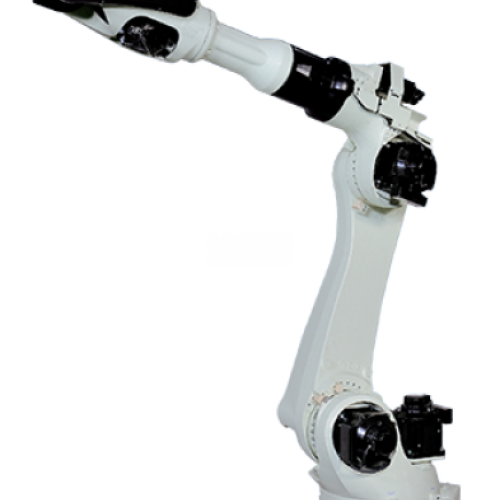

Kawasaki BX130X

The BX130X robot with designed for spot welding with powerfull heavy-duty motors, offers optimization in motion control for greater speed, its compact design and thin arm and wide reach allow a saving of space when installing it and they facilitate the installation in applications of "high density" offering greater flexibility; The structure of manufacturing and engineering minimizes interference with other robots and peripheral devices, this robot can work in highly polluted environments thanks to Kawasaki technology that allows shorter maintenance intervals that provide greater profitability production optimization.

E Controller

E controllers are compact, reliable and high performance, have advanced technology in the CPU allowing greater productivity and trajectory control. Wide range of industrial applications supported by Kawasaki AS technology that uses a programming language that provides sequence control; possible expansion of up to 10 external axes for complete control of 16 axes. Easy maintenance and diagnosis thanks to its modular components and limited cables.

- Ideal for primary energy distribution voltage of each region

- Greater capacity for expansion

- Closed structure with indirect cooling system

- Digital servo system

- I / O channels 32 (max128)

Number of axis: 6

Maximum horizontal reach: 2,991 mm

Maximum vertical reach: 4,211 mm

Repeatability: ± 0.2 mm

Controller: E32

Axis JT2: +76°/-60°

Axis JT3: +90°/-75°

Axis JT4: ±210°

Axis JT5: ±125°

Axis JT6: ±210°

Axis JT2: 90°/s

Axis JT3: 130°/s

Axis JT4: 200°/s

Axis JT5: 160°/s

Axis JT6: 300°/s

Pedestal Spot Welding

Material Handling

Friction Spot Joining

Machine Tending

Material Handling

Material Removal

Spot Welding

Applications

Spotwelding , Handling of parts , Measurement , Assembly of parts

Pictures

Diagrams

English

English

Germany

Germany

France

France

Russia

Russia

China

China

Argentina

Argentina

Portugal

Portugal

Colombia

Colombia

Italy

Italy

India

India

Brazil

Brazil

Japan

Japan

Mexico

Mexico

Turkey

Turkey

Ukraine

Ukraine

Peru

Peru

Sth. Africa

Sth. Africa