The KR DELTA is a compact, high-performance parallel arm robot engineered for pick-and-place tasks, delivering speed, precision, and reliability. Designed to optimize short cycle times and rapidly handle objects, it boasts a payload capacity of three kilograms, making it ideal for automating order picking and packing, especially in the electronics industry. A key advantage of the KR DELTA family is their minimal maintenance needs, thanks to self-lubricating ball joints that eliminate the need for lubricant replacement in the reduction gears.

Available in both a cost-effective standard version and a specialized Hygienic Machine variant, the KR DELTA HM is constructed from stainless steel, suited for rigorous food and medical applications. With an IP67 protection rating, it withstands cleaning and sterilization with high-pressure cleaners and industrial chemicals. Materials used in its construction and lubrication meet FDA and LFGB regulations for food contact.

Key Features:

- High Speed: Capable of achieving cycle times as short as 0.32 seconds.

- Flexible Flange: Allows easy mounting of various tools.

- Large Workspace: Operates within a cylindrical workspace of 350 mm height and 1,200 mm diameter.

- Small Footprint: Ceiling-mounted with an installation area diameter of 350 mm.

- Low Maintenance: Encapsulated gear unit and self-lubricating joints mean no lubricant replacement is necessary.

The KR DELTA comes with the KR C5 micro controller, which is space-efficient and energy-saving, operating at just 230 volts. Direct cleaning with high-pressure cleaners reduces downtime significantly.

For seamless system integration, the KR DELTA utilizes the KUKA.VisionTech application and KUKA.PickControl software, supporting the integration of up to ten robots and conveyor systems. Its versatility spans across processing, order picking, sorting, packaging, and stacking tasks in diverse industries, including electronics, food, medical, and household chemicals.

Main Specifications

- Number of axis: 4

- Maximum load: 6 kg

- Maximum reach: 600 mm

- Maximum diameter: 1200 mm

- Position repeatability: (ISO 9283) ± 0.1mm

- Mounting position: Ceiling

Displacement range

- Axis 1 -120 ° / 40 °

- Axis 2 -120 ° / 40 °

- Axis 3 -120 ° / 40 °

- Axis 4 ± 255 °

- Axis 5 -

- Axis 6 -

Speed at rated load

- Axis 1 168 ° / s

- Axis 2 168 ° / s

- Axis 3 168 ° / s

- Axis 4 162 ° / s

- Axis 5 -

- Axis 6 -

Robot applications

- Pick & Place

- Palletizing

- Packaging

- Assembly

- Handling

- Clean room

Applications

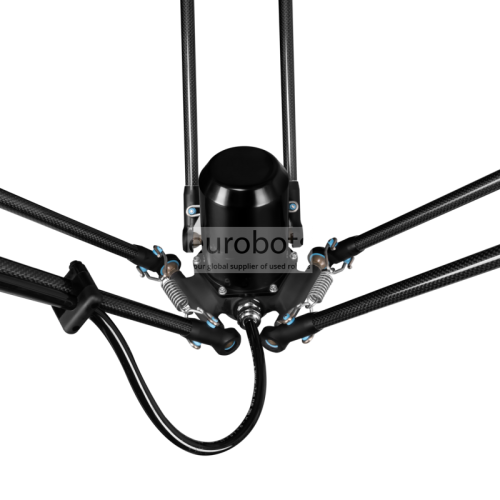

Pictures

Diagrams