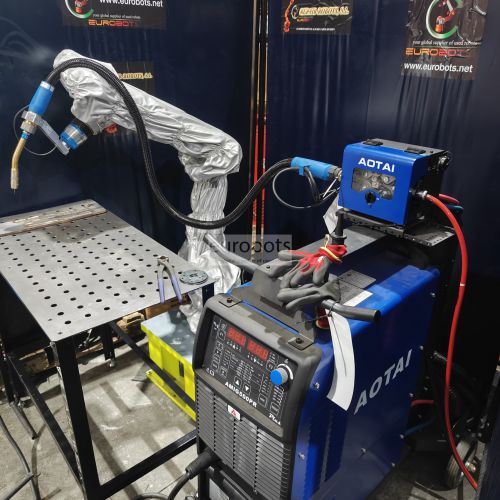

DOBOT CR10 COBOT Welding Solution. Engineered to deliver unparalleled flexibility, efficiency, performance and reliability.

-

Collaborative Robotics: Boosts productivity by working alongside human operators, handling repetitive tasks with precision.

-

Plug&Play: Configured and ready to use, just customize the paramaters for your materials

-

Easy Programming: Intuitive interfaces allow quick setup and reconfiguration, simplifying operation.

-

Flexible: Can change the welding source easily and choose almost any brand (AOTAI, MEGMEET, FRONIUS, OTC, WeldTec...)

At the heart of this innovative system lies a fusion of advanced technologies from industry leaders AOTAI, FRONIUS, and MEGMEET, ensuring unmatched quality and consistency in every weld. Equipped with a TBI torch and anti-collision features, the DOBOT CR10 COBOT ensures not only precise welding but also enhanced safety in operation.

| Model | AMIG350Pro | AMIG500Pro |

| Power supply voltage/Freq | 3~380V±10%,50/60Hz | 3~380V±10%,50/60Hz |

| Rated power capacity(KVA) | 14 | 25.2 |

| Rated input current(A) | 26 | 45 |

| Duty cycle(%) | 100% | 100% |

| Output current range(A) | 60~350 | 60~500 |

| Output voltage range(V) | 17~31.5 | 17~39 |

| OCV(V) | 75 | 75 |

| Wire diameter(mm) | Ф0.8、Ф1.0、Ф1.2 | Ф0.8、Ф1.0、Ф1.2 |

| Torch type | Push | Push |

| Welding process | CV MIG, Pulse,Double pulse, SSAP, CP | CV MIG, Pulse,Double pulse, SSAP, CP |

| Gas flow(L/min) | 15~20 | 15~20 |

| Insulation class | H | H |

| Dimension(mm3) | 635x320x630 | 635x320x630 |

| Weight(kg) | 60 | 60 |

-

FPGA Fully Digital Multi-Core Control System: This innovative system ensures precise control over the welding process, achieving low spatter welding with exceptional accuracy.

-

SLST Super Low Spatter Process: Expertly crafted for thin plate welding, this process reduces spatter by an impressive 95% compared to traditional methods, ensuring clean and precise welds.

-

SSAP Super Short-Arc Pulse Process: Offering higher welding quality and faster welding speeds, this process enhances efficiency without compromising on weld integrity.

-

CP Constant Penetration Process: Delivering high-quality welds, this process is particularly adept at welding narrow gap fillets with ease and precision.

-

CCP Customized Craftsmanship: Tailored to meet individual customer needs, this feature provides a confidential mechanism, ensuring personalized solutions with utmost discretion.

-

FSW Fast Spot Welding Function: Specifically designed for robot high-speed spot welding processes, this function enhances productivity and efficiency in industrial settings.

-

4 Rolls Drive with Fully Digital Double Closed-Loop Grating Feedback Wire Feeding System: This advanced wire feeding system ensures accuracy and stability, facilitating smooth and consistent wire feeding for optimal welding results.

FRONIUS TPS320i

-

Advanced Welding Technology: The TPS 320i utilizes advanced welding technology to provide excellent weld quality and process stability.

-

Dynamic Welding Process Control: It offers dynamic control of the welding process, allowing for precise adjustments to parameters such as voltage, current, and wire feed speed.

-

Synergic Welding Programs: Synergic welding programs simplify setup and operation by automatically adjusting welding parameters based on the selected material type and thickness.

-

Pulse and Double Pulse Welding: The TPS 320i supports pulse and double pulse welding processes, which are particularly useful for thin sheet metal welding and reducing heat input.

-

Versatility: It is suitable for various welding processes including MIG/MAG, TIG, and MMA (Stick) welding, making it adaptable to different welding applications.

-

Energy Efficiency: Fronius is known for its commitment to energy efficiency, and the TPS 320i is designed with energy-saving features to minimize power consumption during operation.

-

User-Friendly Interface: The welding power source features an intuitive user interface with a clear display and easy-to-use controls, enhancing usability and productivity for welders.

MEGMEET Artsen PLUS 500

Applications

Pictures

Videos

Diagrams